Page 17 - Caswell Firesafe Manual 2018

P. 17

Factors affecting Bearer specification

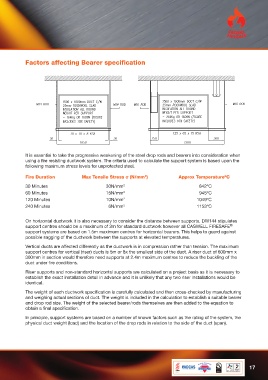

It is essential to take the progressive weakening of the steel drop rods and bearers into consideration when

using a fire resisting ductwork system. The criteria used to calculate the support system is based upon the

following maximum stress levels for unprotected steel.

2

Fire Duration Max Tensile Stress σ (N/mm ) Approx TemperatureºC

30 Minutes 30N/mm 2 842ºC

60 Minutes 15N/mm 2 945ºC

120 Minutes 10N/mm 2 1049ºC

240 Minutes 6N/mm 2 1153ºC

On horizontal ductwork it is also necessary to consider the distance between supports. DW144 stipulates

support centres should be a maximum of 3m for standard ductwork however all CASWELL FIRESAFE ®

support systems are based on 1.5m maximum centres for horizontal bearers. This helps to guard against

possible sagging of the ductwork between the supports at elevated temperatures.

Vertical ducts are affected differently as the ductwork is in compression rather than tension. The maximum

support centres for vertical (riser) ducts is 5m or 8x the smallest side of the duct. A riser duct of 600mm x

300mm in section would therefore need supports at 2.4m maximum centres to reduce the buckling of the

duct under fire conditions.

Riser supports and non-standard horizontal supports are calculated on a project basis as it is necessary to

establish the exact installation detail in advance and it is unlikely that any two riser installations would be

identical.

The weight of each ductwork specification is carefully calculated and then cross-checked by manufacturing

and weighing actual sections of duct. The weight is included in the calculation to establish a suitable bearer

and drop rod size. The weight of the selected bearer/rods themselves are then added to the equation to

obtain a final specification.

In principle, support systems are based on a number of known factors such as the rating of the system, the

physical duct weight (load) and the location of the drop rods in relation to the side of the duct (span).

17