Page 11 - Caswell Firesafe Manual 2018

P. 11

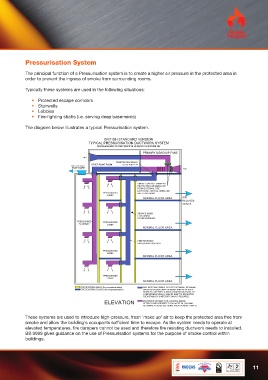

Pressurisation System

The principal function of a Pressurisation system is to create a higher air pressure in the protected area in

order to prevent the ingress of smoke from surrounding rooms.

Typically these systems are used in the following situations:

• Protected escape corridors

• Stairwells

• Lobbies

• Fire-fighting shafts (i.e. serving deep basements)

The diagram below illustrates a typical Pressurisation system.

BRITISH STANDARD VERSION

TYPICAL PRESSURISATION DUCTWORK SYSTEM

DIAGRAM BASED ON THE PRINCIPLE OF EN12101-6 (FIGURE 8B)

PRIMARY & BACKUP FANS

PENETRATION SEALS

OTHER PLANT ROOM TO BS 476 PT24

OVER PRESSURE

RELIEF DAMPER

SMOKE CONTROL DAMPERS

PROTECTING INCOMING AIR

FROM EXTERNAL FIRE

EXPOSURE - WITH ALTERNATIVE

PRESSURISED INLET POSITIONS

LOBBY

NORMAL FLOOR AREA AIR

RELEASE

VENTS

SERVICE RISER

CONTAINING

OTHER SERVICES

PRESSURISED PRESSURISED

STAIRWAY LOBBY

NORMAL FLOOR AREA

FIRE RESISTING

PRESSURISATION DUCT

PRESSURISED

LOBBY

NORMAL FLOOR AREA

PRESSURISED

LOBBY

NORMAL FLOOR AREA

FIRE RESISTING WALLS (for compartmentation) FIRE RESISTING SMOKE OUTLET DUCTWORK, RETAINING

FIRE RESISTING FLOORS (for compartmentation) CROSS SECTIONAL AREA OF MORE THAN 75 OF DUCT.

STABILITY, INTEGRITY & INSULATION RATING EQUAL TO

COMPARTMENT WALLS, UNLESS SHAFT IS DEDICATED,

THEN STABILITY & INTEGRITY ONLY IS REQUIRED

ELEVATION DUCTWORK SUITABLE FOR CLEARING SMOKE.

OFTEN 1 HOUR INTEGRITY TO BS 476 PT 24 - ISO 6944

RETAINING A CROSS SECTIONAL AREA OF MORE THAN 75.

These systems are used to introduce high-pressure, fresh 'make up' air to keep the protected area free from

smoke and allow the building's occupants sufficient time to escape. As the system needs to operate at

elevated temperatures, fire dampers cannot be used and therefore fire resisting ductwork needs to installed.

BS 9999 gives guidance on the use of Pressurisation systems for the purpose of smoke control within

buildings.

11